Finished my degree that is... apologies for the complete lack of blogging over the last few weeks but it had to go, along with cooking, laundry, in fact any housework at all, and even, at times, sleeping.

Am I glad I did it? Yes. Am I glad it's over? YES!

So here are some pictures of my final collection of work. They're not the most brilliant photographs, I seem to have created work that is camera shy, but I've done my best to capture it and please take my word that everything looks better in real life!

There are more pictures over on my new website. And normal blogging service should be resumed here shortly...

Showing posts with label degree course. Show all posts

Showing posts with label degree course. Show all posts

Saturday, 6 July 2013

Tuesday, 23 April 2013

Drawing the horizon

I'm still plugging away, firing more and more glass strips. I laid out all the ones I'd done so far this morning.

It's getting there, but not quite what I want yet. I lined them all up a bit better and added the prints for the next sets of strips to the end and it began to look a bit more like it...

Laying the strips nice and straight rather than a bit haphazard made quite a difference; it's something I'm going to have to take into consideration when I'm fixing them all together.

(Apologies for the poor photographs, it's not easy to find the space to lay them all out, impossible to find somewhere with good lighting as well!)

It's getting there, but not quite what I want yet. I lined them all up a bit better and added the prints for the next sets of strips to the end and it began to look a bit more like it...

Laying the strips nice and straight rather than a bit haphazard made quite a difference; it's something I'm going to have to take into consideration when I'm fixing them all together.

(Apologies for the poor photographs, it's not easy to find the space to lay them all out, impossible to find somewhere with good lighting as well!)

Wednesday, 3 April 2013

Something completely different...

Towards the end of April, as part of our course, the final year students will be creating a pop-up gallery/shop in Wrexham, and we are tasked with stocking it with lovely things at affordable prices. Since the glass pieces I have been working on are somewhat experimental I wasn't sure that they would be suitable (or finished!) so I have gone back to my first love, textiles, and combined it with my second love, printmaking.

I've used various scraps of trim and edgings, some vintage, some reclaimed and some just 'spare', to make a series of collagraph plates. It's a great way to use pieces that are too small for much else, and even pieces that are falling apart; they can be 'repaired' when they are glued to the plate. All you need to remember when you're making the plates is that you can ignore the colour and just concentrate on the texture.

My idea was to create printed backgrounds from the trims onto which I could add 'real' pieces of trim. I originally thought I would ink the plates in a brown colour to give that vintage feel, but I didn't really like the results, even the palest colour seemed to overpower the delicate pattern and texture.

So I decided to stick to blind embossing, which is a much quicker and cleaner process without the ink, better all round! I've been having fun 'auditioning' buttons from my button tin and scraps of trim from my ribbon box and I have finally made some decisions and sewn a few on... I'm struggling to decide which is my favourite. What do you think?

The paper size for these prints is just under A5; I think the size works well with the scale of the elements. I am wondering whether to do some A4 sized ones as well or whether the extra 'bits and pieces' needed to fill the space will make them look too cluttered.

When I'm embossing I nearly always have a few disasters where either the plate or the paper moves and the whole thing ends up crooked. There's nothing really that can be done with those prints except tear them up, which is ideal for making cards.

I was so pleased with these cards that I made a couple more prints on scraps of paper just so I could make some extra for my Etsy shop; I'll be listing them just as soon as I get some decent photographs.

And if you're anywhere near Wrexham during the week 22nd to 26th April, do pop along to the People's Market to see what other lovely things we have on show.

I've used various scraps of trim and edgings, some vintage, some reclaimed and some just 'spare', to make a series of collagraph plates. It's a great way to use pieces that are too small for much else, and even pieces that are falling apart; they can be 'repaired' when they are glued to the plate. All you need to remember when you're making the plates is that you can ignore the colour and just concentrate on the texture.

My idea was to create printed backgrounds from the trims onto which I could add 'real' pieces of trim. I originally thought I would ink the plates in a brown colour to give that vintage feel, but I didn't really like the results, even the palest colour seemed to overpower the delicate pattern and texture.

So I decided to stick to blind embossing, which is a much quicker and cleaner process without the ink, better all round! I've been having fun 'auditioning' buttons from my button tin and scraps of trim from my ribbon box and I have finally made some decisions and sewn a few on... I'm struggling to decide which is my favourite. What do you think?

The paper size for these prints is just under A5; I think the size works well with the scale of the elements. I am wondering whether to do some A4 sized ones as well or whether the extra 'bits and pieces' needed to fill the space will make them look too cluttered.

When I'm embossing I nearly always have a few disasters where either the plate or the paper moves and the whole thing ends up crooked. There's nothing really that can be done with those prints except tear them up, which is ideal for making cards.

I was so pleased with these cards that I made a couple more prints on scraps of paper just so I could make some extra for my Etsy shop; I'll be listing them just as soon as I get some decent photographs.

And if you're anywhere near Wrexham during the week 22nd to 26th April, do pop along to the People's Market to see what other lovely things we have on show.

Tuesday, 26 March 2013

Progress and Setbacks

Since I posted about finding a technique I wanted to explore, I had a bit of a setback. I did a series of experiments and made various samples and, all of a sudden, it stopped working. Cue a mild attack of panic and a series of unsuccessful experiments, followed by a quiet afternoon trying to remember what on earth, what tiny, seemingly insignificant thing, I had done differently before. Fortunately it dawned on me, I had an anxious day waiting for the test kiln firing to finish, but it worked... phew!

So I've been putting together some little glass-and-wire fences. Or maybe trees.

The next issue to sort out was the wire; the first one I used broke when it was twisted tightly. The next one was a bit flimsy; although I do want to channel broken down fences, not so much that I can't get the thing to stand up at all...

On to the next wire; this one is quite a bit thicker and I did think it might be too thick, but I'm pleased with the way it has turned out. The pieces have a nice sturdy feel to them and I do like the black colour of the wire. Although I might attack it with a little salt and vinegar and see what happens...

And so, on to the next challenge, to sort out the image printed on the glass. Currently it's a bit too 'all over' for my liking.

So I've been putting together some little glass-and-wire fences. Or maybe trees.

The next issue to sort out was the wire; the first one I used broke when it was twisted tightly. The next one was a bit flimsy; although I do want to channel broken down fences, not so much that I can't get the thing to stand up at all...

On to the next wire; this one is quite a bit thicker and I did think it might be too thick, but I'm pleased with the way it has turned out. The pieces have a nice sturdy feel to them and I do like the black colour of the wire. Although I might attack it with a little salt and vinegar and see what happens...

And so, on to the next challenge, to sort out the image printed on the glass. Currently it's a bit too 'all over' for my liking.

Thursday, 28 February 2013

Finding my way

Isn't it funny how trying just one thing can suddenly make everything fall into place? And about time too you might say, as I am very nearly at the end of my degree course.

Isn't it funny how trying just one thing can suddenly make everything fall into place? And about time too you might say, as I am very nearly at the end of my degree course.In the first year of the course I fell in love with collagraph printing. Creating the plates; the way the ink echoed the texture of the plate and the unpredictability of the print itself; the variations in the strength of the marks; everything.

Ever since then I have, sometimes consciously and sometimes not, been trying to replicate that effect in glass.

First I tried copying the images I had created from the collagraphs and screenprinting them onto the glass. That worked, up to a point, but for me the screenprinting process meant that the images lost the essential sense of texture that they had as prints on paper. They were just too definite, too clean.

Then I tried creating plaster moulds in the same way that I create collagraph plates and casting the glass in these moulds.

So far the results of this have been somewhat unpredictable. I dare say if I pursue it, eventually I will get it to work as I want, but it is a time consuming process, and also one which uses a lot of expensive glass frit. I have also realised that to do this I will have to get used to using more robust materials to create my textures; both to stand up to the mould making process and to create definite enough marks on the glass; and I'm not sure that I want to change my materials so much.

But then the other day I had one of those 'I haven't tried that' moments and these little printed strips were the result.

They may not look much but I am very excited about them. The print on the back of the glass was taken from one of my collagraph prints; the glass was laid on top of it in the kiln and has 'picked up' the image, but in a much more interesting and sketchy way than a direct screenprint. There is just enough texture on the back of the glass; I can see endless possibilities in these two little strips of glass...

Thursday, 24 May 2012

Almost done

Very nearly at the end of my second year at uni now, the final assessment is over, we've had the last lecture, just tidying up now and helping the third years get ready for their degree show. The year seems to have rushed past extremely quickly, I have learned a lot but this has only highlighted to me how much I still have to learn. Ah well, learning is good.

I didn't quite get what I wanted (i.e. free standing forms) from this final project; I ended up with one rather distorted free standing form, a set of 3 broken bits, and a rather nice piece which doesn't curve enough to stand by itself but miraculously slots together with the one that does. So we took what I had down to the beach again, in rather better weather this time.

You might have noticed that I have credited my photographer; I did take some photographs but his were so much better! And at least this time he had worked out how to use the flip out screen on the camera so he didn't have to lie on the wet sand... He will be off to college in the autumn to continue his own artistic journey; you can see some more of his work here.

|

| Photograph by Russell Smith |

I didn't quite get what I wanted (i.e. free standing forms) from this final project; I ended up with one rather distorted free standing form, a set of 3 broken bits, and a rather nice piece which doesn't curve enough to stand by itself but miraculously slots together with the one that does. So we took what I had down to the beach again, in rather better weather this time.

|

| Photograph by Russell Smith |

While I didn't manage to control the form I am pleased with the textures and the effect of mixing the wire with the glass. And the colours are very me, and very in keeping with our beach, which 'my' colours always seem to be.

|

| Photograph by Russell Smith |

|

| Photograph by Russell Smith |

|

| Photograph by Russell Smith |

You might have noticed that I have credited my photographer; I did take some photographs but his were so much better! And at least this time he had worked out how to use the flip out screen on the camera so he didn't have to lie on the wet sand... He will be off to college in the autumn to continue his own artistic journey; you can see some more of his work here.

Saturday, 21 April 2012

More glass... and some knitting

This week I have been attracting attention by sitting in the canteen at uni knitting with wire. Having previously related mostly to textiley people this seemed a perfectly normal activity to me (along with setting fire to things in the car park and wrapping up any old stuff I find...) but as there isn't a textiles course at my uni this simple act seemed to be a huge novelty to most people!

Having knitted my wire I then attacked it with scissors and deconstructed it a bit, and layered it up with scraps of float glass something like this ------>

Having knitted my wire I then attacked it with scissors and deconstructed it a bit, and layered it up with scraps of float glass something like this ------>

This picture was taken on the workbench so by the time I'd transferred all the bits to the kiln it wasn't quite the same, but near enough.

A bit of guess work with the kiln program (it always is) meant that the result was flatter and less 'lumpy' than I intended but I was thrilled with the way the wire reacted and with the texture the glass picked up underneath. I hope you're ready to look through loads of pictures now... To give you an idea of scale they are each about 30cm tall.

And one without wire just to see...

Having knitted my wire I then attacked it with scissors and deconstructed it a bit, and layered it up with scraps of float glass something like this ------>

Having knitted my wire I then attacked it with scissors and deconstructed it a bit, and layered it up with scraps of float glass something like this ------>This picture was taken on the workbench so by the time I'd transferred all the bits to the kiln it wasn't quite the same, but near enough.

A bit of guess work with the kiln program (it always is) meant that the result was flatter and less 'lumpy' than I intended but I was thrilled with the way the wire reacted and with the texture the glass picked up underneath. I hope you're ready to look through loads of pictures now... To give you an idea of scale they are each about 30cm tall.

And one without wire just to see...

Friday, 30 March 2012

At last, some glass

It seems I start every post by apologising for not posting more often, which is a bit daft really. But now I have a couple of weeks off for Easter so I can catch up with all some of the things I haven't had time to do lately.

So I thought you might like to see some pictures of what I've been working on at uni lately. Our last module required us to produce a 'marketable product' within a certain price bracket and to research selling venues and produce marketing material and so on. I rather enjoyed this module, I got to do some maths as well as some making.

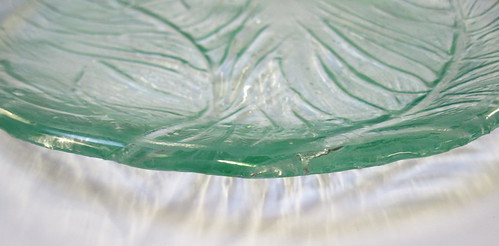

My design idea was to produce a range of textured dishes on a textile related theme. Opting to work with texture rather than colour was quite challenging as I had to hand make moulds for each of my designs but I really wanted to see whether I could do it quickly enough to produce something affordable.

The textures are from some beautiful vintage Indian printing blocks I have. Once I had made the moulds I started off working with float/window glass. I like the way the green tint of the glass works with the texture, and it has the advantage of not being so horribly expensive that mistakes are a disaster.

This one was supposed to be the same rectangular shape as the other but due to a rather messy leak the plaster mould was too thin and snapped in half. So I went ahead and used the broken half a mould and I think it works rather nicely as a square - this one was a happy accident!

Having proved that the moulds worked fine with float glass, I really really wanted to use coloured glass. We're getting more expensive now! Unfortunately the glass behaves quite differently from float glass and needs a completely different firing programme and although everyone had an idea, nobody really knew what programme I should be using.

Cue quite a few disasters (and remember we're using the expensive stuff...). First we went too hot and ended up with sharp points on the edges, and pulled edges, and a hole where the glass had bubbled and burst. Unfortunately there were 3 of these :(

Although, some parts are really lovely so I am hoping to be able to cut away the dodgy bits and do something with the remainder.

Then we went too cold and had to try again... and when we did it was too hot again!

Finally, more by luck than judgement, we got it right...

So now I know the firing programme to use for this particular glass provided I fire it at the right hand end of that particular kiln... don't ever let anyone tell you glass is an easy medium to work with!

But I am so pleased with the result it was definitely worth the ups and downs. And more importantly, I developed an efficient and cost-effective method of making the moulds I need.

So, finally the acid test, I'll be listing some of the dishes in my etsy shop next week and I'll find out whether I really did come up with a marketable design!

So I thought you might like to see some pictures of what I've been working on at uni lately. Our last module required us to produce a 'marketable product' within a certain price bracket and to research selling venues and produce marketing material and so on. I rather enjoyed this module, I got to do some maths as well as some making.

My design idea was to produce a range of textured dishes on a textile related theme. Opting to work with texture rather than colour was quite challenging as I had to hand make moulds for each of my designs but I really wanted to see whether I could do it quickly enough to produce something affordable.

The textures are from some beautiful vintage Indian printing blocks I have. Once I had made the moulds I started off working with float/window glass. I like the way the green tint of the glass works with the texture, and it has the advantage of not being so horribly expensive that mistakes are a disaster.

This one was supposed to be the same rectangular shape as the other but due to a rather messy leak the plaster mould was too thin and snapped in half. So I went ahead and used the broken half a mould and I think it works rather nicely as a square - this one was a happy accident!

Having proved that the moulds worked fine with float glass, I really really wanted to use coloured glass. We're getting more expensive now! Unfortunately the glass behaves quite differently from float glass and needs a completely different firing programme and although everyone had an idea, nobody really knew what programme I should be using.

Cue quite a few disasters (and remember we're using the expensive stuff...). First we went too hot and ended up with sharp points on the edges, and pulled edges, and a hole where the glass had bubbled and burst. Unfortunately there were 3 of these :(

Then we went too cold and had to try again... and when we did it was too hot again!

Finally, more by luck than judgement, we got it right...

So now I know the firing programme to use for this particular glass provided I fire it at the right hand end of that particular kiln... don't ever let anyone tell you glass is an easy medium to work with!

But I am so pleased with the result it was definitely worth the ups and downs. And more importantly, I developed an efficient and cost-effective method of making the moulds I need.

So, finally the acid test, I'll be listing some of the dishes in my etsy shop next week and I'll find out whether I really did come up with a marketable design!

Wednesday, 2 November 2011

Platemaking

I have been madly busy this week trying to get on with the practical part of our first assignment of the term. Between a team of us we have to produce an 8 place table setting. That's 8 of everything. I'm making plates. 8 of them.

I have been working my way through the casting process I want to use, finding out what works and what doesn't. It's quite a long winded process; first make a clay form of the plate...

...then make a plaster mould of the clay form, carefully clean out all the little bits of clay left behind and wait several days for it to be dry enough to use.

Drill the base of the mould full of holes to let the air escape during casting, and place in the kiln. Cut 2 circles of glass and place in the mould in the kiln. Cook overnight, keeping fingers crossed. And if I'm very lucky the result will be a glass plate with no lumpy bubbles (glass is so hard to photograph)...

Repeat. With a bit of luck, and if it is not moved, a mould can be used 2 or 3 times before it really starts to crumble.

2 down, 6 to go!

I have been working my way through the casting process I want to use, finding out what works and what doesn't. It's quite a long winded process; first make a clay form of the plate...

...then make a plaster mould of the clay form, carefully clean out all the little bits of clay left behind and wait several days for it to be dry enough to use.

Drill the base of the mould full of holes to let the air escape during casting, and place in the kiln. Cut 2 circles of glass and place in the mould in the kiln. Cook overnight, keeping fingers crossed. And if I'm very lucky the result will be a glass plate with no lumpy bubbles (glass is so hard to photograph)...

Repeat. With a bit of luck, and if it is not moved, a mould can be used 2 or 3 times before it really starts to crumble.

2 down, 6 to go!

Saturday, 2 April 2011

A decision?

As you probably know, the degree course I am on requires you to choose a specialism - the choice is Ceramics, Jewellery/Metalwork or Glass. Very very difficult! When I started I was fairly sure that I would choose metalwork and go on to combine it with my textile work.

But then I discovered that working in glass can give you all the elements of texture and layering that I love to play with in my textile work, and I was hooked!

This week we have been doing low-relief casting in the kiln, creating moulds by cutting up pieces of fibre blanket to give form and texture. We layered cut pieces of fibre blanket and sheets of float (window) glass - if the pieces of blanket go right to the edge you can put them between the sheets of glass to create gaps too.

My design all layered up and nearly ready to go - the edges just need to be trimmed.

In the kiln, surrounded by pieces of kiln shelf to keep it in place.

And this is how it came out!

Now, I didn't have this in mind when I designed the piece, but isn't it perfect?

But then I discovered that working in glass can give you all the elements of texture and layering that I love to play with in my textile work, and I was hooked!

This week we have been doing low-relief casting in the kiln, creating moulds by cutting up pieces of fibre blanket to give form and texture. We layered cut pieces of fibre blanket and sheets of float (window) glass - if the pieces of blanket go right to the edge you can put them between the sheets of glass to create gaps too.

My design all layered up and nearly ready to go - the edges just need to be trimmed.

In the kiln, surrounded by pieces of kiln shelf to keep it in place.

And this is how it came out!

Now, I didn't have this in mind when I designed the piece, but isn't it perfect?

Subscribe to:

Posts (Atom)